- Even more powerfulCombination of Robustness and EleganceNO TERRAIN CAN RESIST ITPowerful lines that leave nothing to chancePrevious slideNext slide

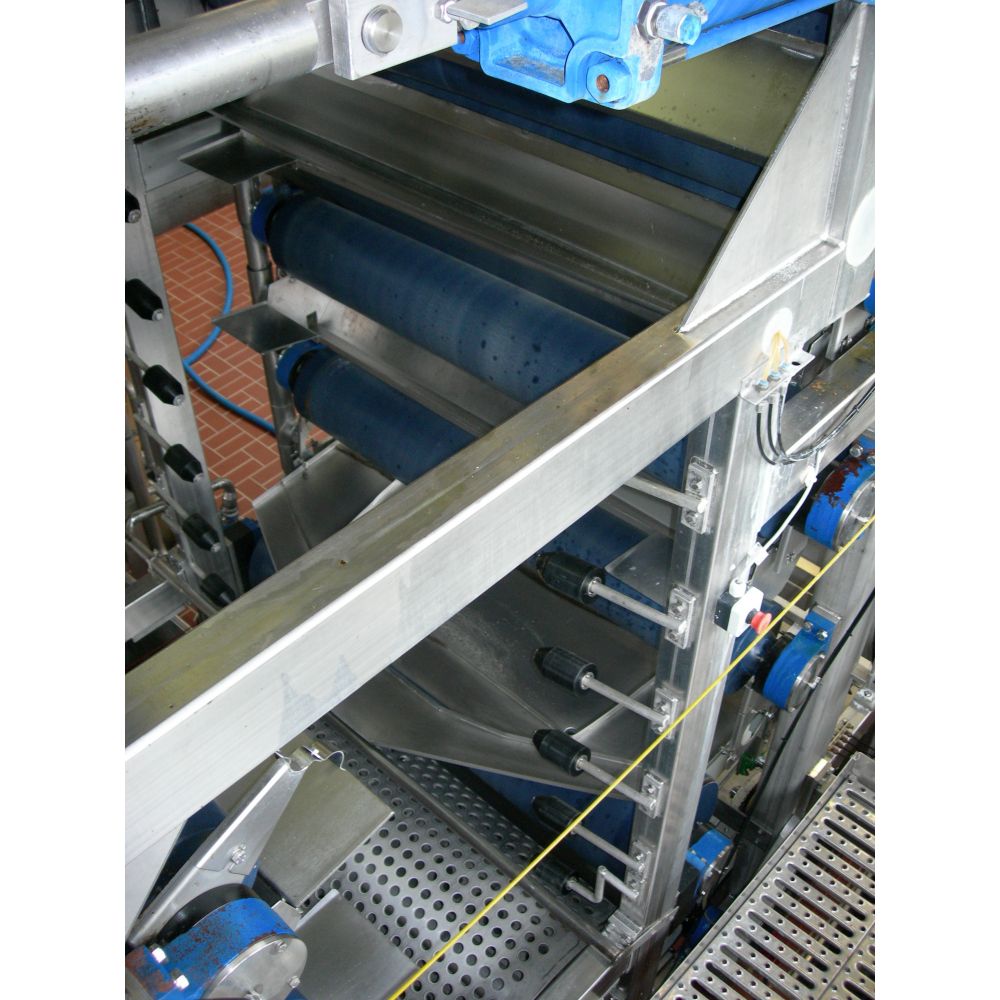

Pressing Station APEX 1600

The advantages of the APEX Pressing station are universal application for several kind of fruits, we have experience with

- Apples, Pears, Grape juice, Cherries, Strawberries, Red currants

High yield even with stored fruit

Counter – current extraction can be switched on or off

Technical Data:

- Capacity 14 t / h

- Length 6646 mm

- Width 4110 mm

- Height 5630 mm

- Weight 8000 kg

- Width of belt 1500 mm

- Speed of belt 0-11 m/min

- Air pressure min. >4 bar

- Air pressure max. 8 bar

- Belt tension min. 4 bar

- Belt tension max. 6 bar

- Air consumption (free of water, oil, dust) 2 m³ / h

- Water consumption for belt cleaning 1800 l / h

- “Leaching water in % of mash “ 0-20 %

- Electric connection

- Belt drive 240 / 400 V 11,5 kW

- Brush drive 240 / 400 V 2x 2,2 kW

- Cleaning water backflow pump 240 / 400 V 2x 0,55 kW

- Motor of Belt cleaning 240 / 400 V 2x 0,25 kW

Description of the pressing station

The Eurolux belt press APEX 1600 is a continuous pressing system for the production of fruit juice.

By adding water directly in the press, the extraction of pomace takes place at the same moment. The aim is to get the remaining sellable matter, especially sugar, in the pomace, allowing to increase the yield.

The press is either directly fed the mill or the mash is fed into the feeding hopper, via a variable pump. Thanks to a quick regulation it is possible to adjust the optimum thickness of the mash cake.

A first very big roller increases slowly the pressure and allows a quick and extensive deducing.

A total of 12 rollers ensures an optimal big pressing surface of 12 m², enabling to reach a yield up to 85 – 88 kg juice.

The vertical construction of the press allows a multi – step counter – current extraction, i.e. water is given to the pomace cake from the end press roller.

The water is aspirated by pomace and dissolves the remaining sugar.

In the end pressing zone, the pomace is pressed out, so that there is, according to mash condition, as less humidity left as possible.

Because of the pomace outlet, being at the top, the pomace can be conveyed horizontally by a screw.

The belt cleaning device takes care of a proper cleaning of the belt. By means of a continuous an constant high pressure belt cleaning, no cleaning breaks are necessary.

To reduce water consumption to the minimum level, the water for belt cleaning is recycled and screened by relative screen. The water required for the extraction is taken from the circulating water which has three advantage:

- the sugar dissolved in the cleaning water foes into the juice

- the water taken for the extraction is replaced by fresh water so that the cleaning water is replaced

- the water consumption is reduced to the water quantity used for extraction.

The pressed juice is fed onto a vibratory screen. There, particles are removed and returned to the mash feed by a pump

Instruction Manual Available

Data sheet

| Material | AISI304 (V2A) 1.4301 |

Avis

Il n’y a pas encore d’avis.